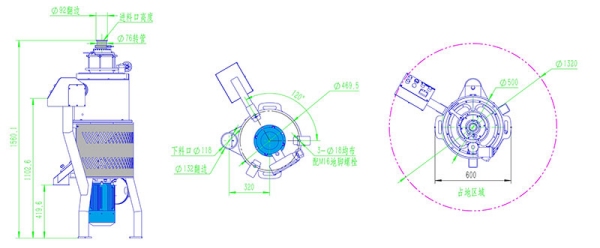

HTQM35Q Buckwheat Shelling Machine

HTQM35Q Buckwheat Dehulling Machine is mainly used for the shelling of sweet buckwheat and tartary buckwheat. It is suitable for large, medium and small buckwheat processing factory. It also can be used alone or the whole production line. HTQM series buckwheat dehulling machine solves some main problems of low hulling rate, low whole rice rate, high broken, insufficient wheat grains, and low yield during the buckwheat processing. It is equipped with large and medium-sized complete buckwheat processing equipment, which is convenient for process layout.

Working Process

1. The raw materials of buckwheat must be cleaned and classified before shelling. The soil, stones, large impurities, small impurities, light impurities, etc., are removed from the raw materials by the multi-functional trash remover.

2. After the cleaned buckwheat is moistened, it is lifted by the bucket elevator to the multifunctional grading sieve for grading, and then through the feeding device, it can enter the buckwheat hulling machine for dehulling processing.

3. The dehulled buckwheat and hulls separated by air sieve cleaner vibrating grading sieve and pack them separately.

Technical Aavantages

1. Direct-connected drive motor: reduce the force of the bearing and increase the service life of the bearing shaft.The sand disc will run smoothly;

2. Simple operation: electric adjustment of sand disc gap, improved electric control with self-locking function, easy operation.

3. Frequency conversion speed regulation: During the shelling process, the spindle speed can be adjusted to achieve the effect of the highest shelling rate and reduce the crushing rate;

4. Patent product: Super hard diamond sanding disc, which is more than 5 times the service life of traditional sanding discs.

Finished Product

Technical Parameter

|

Type |

Capacity(t/h) |

Power(kw) |

Dimension(mm) |

|

HTQM30 |

0.2-0.3 |

1.5+0.2 |

920×710×1556 |

|

HTQM35Q |

2-3 |

7.5+0.2 |

920×871×2384 |

20 Corn and Grain Peeling Machines Equipped with Diesel Engines Shipped to Kenya

20 Corn and Grain Peeling Machines Equipped with Diesel Generators Successfully Loaded and Shipped to Kenya.

Vietnam 6Tons/Hour PeaS Cleaning and Peeling Line Successfully Shipped

On April 10, 2025, the 6-ton/hour peas cleaning and peeling production line ordered by a Vietnamese client was successfu

20T Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete sets