2TPH Sorghum Cleaning and Peeling Production Line

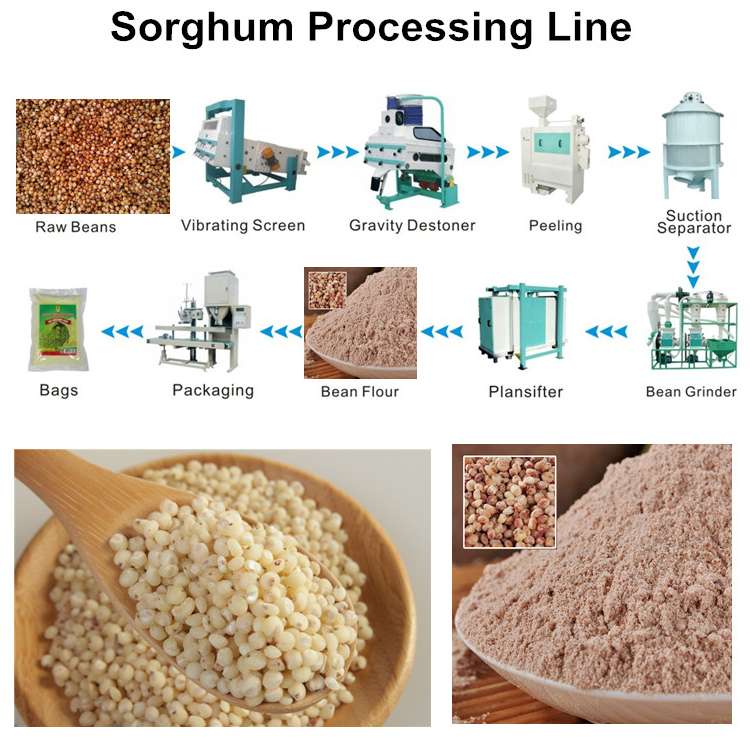

Sorghum Processing Line is used for cleaning, hulling, milling (peeling and polishing), grading, color sorting, packaging sorghum. The Sorghum Processing Line consists of sorghum processing equipments (e.g.: sorghum huller, sorghum rice miller and polisher, color-sorter, etc.) and foodstuff processing general equipments (e.g.: hoist, de-stoner, H-efficient vibrating sifter etc.). The line can process sorghum rice, and the finished products are series of sorghum rice and feed.

Sorghum Processing Line Technical Description

1. The raw material is elevated to cleaning process where double sifters and destoners are installed. The vibration screen effectively clean big and small impurities; the destoner completely removes heavy impurities like stones and mud; The magnetic separator is mainly used to clean out the metal, greatly increasing purity of the finished products; the collector gathers the impurities.

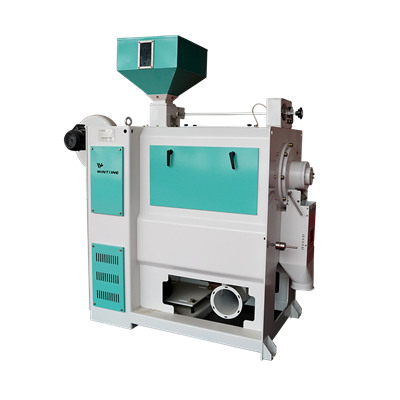

2. The purified materials go to the processing procedure where two emery and iron roll hullers are installed. The emery roll huller is a new equipment well designed and developed according to clients’ requirements; the spiral conveyor is used to charge in the material by force with stable flow but small amount of brokens. The huller is equipped with indicator to display current and voltage, regulator to adjust multiple ventilation doors; the advanced wear resistant parts in the machine are durable. The iron roll huller is effective and stable; the spiral conveyor is used to charge in the material but force with stable flow by small amount of brokens. The huller is equipped with indicator to display current and voltage, regulator to adjust multiple ventilation doors; the wear resistant parts in the machine are of advanced technology.

3. The hulled sorghum is elevated to the polisher to be whitened and sifted out the brokens with double-case plansifter. Then they go to the color grader to be selected out the the particles of different color.

4. Byproducts(husks, flour) from emery roll and iron roll hullers and polishers are individually packaged by packaging cabinet.

Sorghum Processing Line Features

The line adopt the most advanced technology, which can save more energy.

The line has simple structure, high adjustability for the field area and the workshop.

It has simple installation and short construction period.

It can effectively cut down the fixed investment.

It has high yield, inclusion-free of the finished sorghum.

Technical Function and Consumption

1. Raw material

Volume weight: no less than 740g/L

brokens: less than 3%

impurity: less than 1%

moisture: less than 14.5%

2. Power: 220V&380V, 50Hz(or according to the buyer's local condition);

3. Water: public water up to drinking standard under 30℃, average flow meets production and life requirements;

4. Main design index:

Capacity: 20-500tpd in normal condition

Workshop environmen: Dust concentration ≤15mg/m³

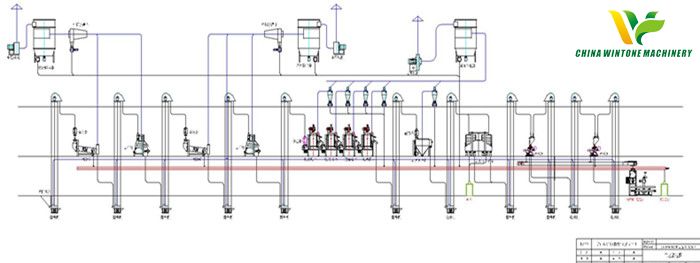

2TPH Sorghum Processing Line was installed in Botswana successfully. The project has automatic control system, which mainly includes bucket elevator, cleaning machines, sorghum peeling machine, packaging machine, etc.

Win Tone sorghum processing equipment is the perfect choice for millet and sorghum processing.

20 Corn and Grain Peeling Machines Equipped with Diesel Engines Shipped to Kenya

20 Corn and Grain Peeling Machines Equipped with Diesel Generators Successfully Loaded and Shipped to Kenya.

Vietnam 6Tons/Hour PeaS Cleaning and Peeling Line Successfully Shipped

On April 10, 2025, the 6-ton/hour peas cleaning and peeling production line ordered by a Vietnamese client was successfu

20T Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete sets