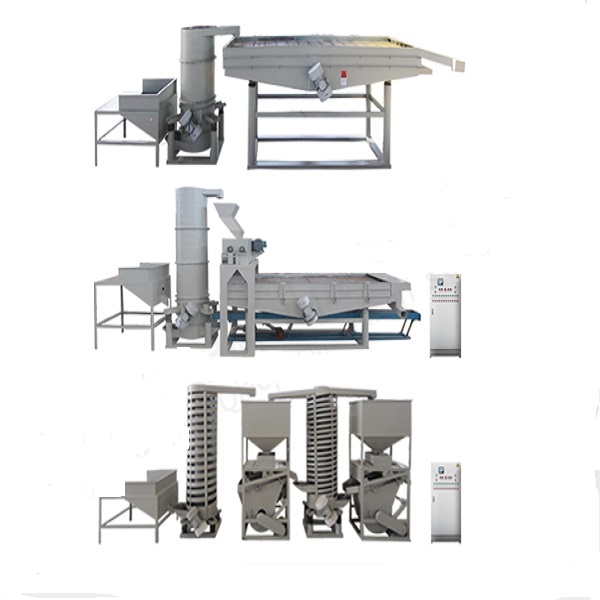

LTC Series Castor Bean Dehulling Equipment

LTC Castor Bean Dehulling Equipment is Win Tone' s original technology. It can quickly and efficiently shell and separate nuts-kernels to obtain pure castor kernels, while reducing processing losses and improving the yield of finished products.

Working Principle

The castor bean enter the huller, turn on the feeding switch, and the feeding flow rate is adjusted. Under the action of the high-speed rotating centrifugal disc, the bonding force between the shell and the kernel of the castor bean is weakened, thereby achieving shell kernel separation. The entire process is highly automated and easy to operate.

Features

1. Effective Peeling Performance

The LTC series castor bean dehulling equipment can accurately and efficiently remove the outer husk of castor bean, ensuring high material utilization and quality.

2. Energy Saving & Reduced Consumption

The LTC series castor bean dehulling equipment adopts a graded husk-removal process, allowing for adjustable air volume, which reduces energy consumption during peeling and lowers production costs.

3. Stable Performance

The LTC series castor bean dehulling equipment is manufactured with high-quality materials and advanced technology, ensuring stable operation and a long service life.

4. Intelligent Equipment

The electrical control system utilizes PLC programming for automated, AI-assisted operation.

Finished Product

Technical Parameter

|

Type |

Capacity(t/h) |

Power(kw) |

Dimension(mm) |

|

LTC30 |

0.2-0.3 |

1.5+0.2 |

920×710×1556 |

|

LTC35Q |

2-3 |

7.5+0.2 |

920×871×2384 |

20 Corn and Grain Peeling Machines Equipped with Diesel Engines Shipped to Kenya

20 Corn and Grain Peeling Machines Equipped with Diesel Generators Successfully Loaded and Shipped to Kenya.

Vietnam 6Tons/Hour PeaS Cleaning and Peeling Line Successfully Shipped

On April 10, 2025, the 6-ton/hour peas cleaning and peeling production line ordered by a Vietnamese client was successfu

20T Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete sets