Buckwheat Hulling and Milling Processing Plant

Innovative Buckwheat Processing Technologies

The complete set of buckwheat processing equipment enables effective separation of husks, bran, kernels, and crushed powder by adjusting the technical parameters of the hulling machine and screening devices. The entire process adopts a fully enclosed, fully negative-pressure dust removal system, revolutionizing traditional hulling techniques and overcoming common issues such as excessive workshop dust and non-compliance with environmental requirements.

Sweet Buckwheat Grain Production Process:

Raw sweet buckwheat selection → Cleaning → Grading → Hulling → Screening → Color sorting → Packaging (finished product).

Tartary Buckwheat Grain Production Process:

Raw tartary buckwheat selection → Cleaning → Soaking → Steaming → Drying → Hulling → Roasting → Packaging (finished product).

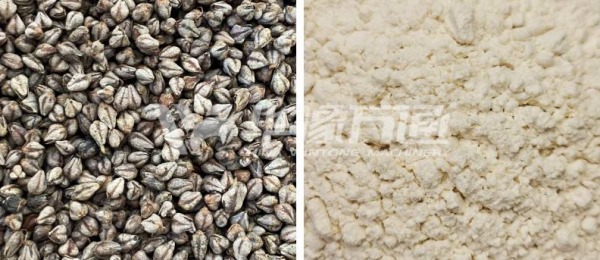

Tartary Buckwheat Flour Production Process:

Tartary buckwheat flour is made from tartary buckwheat through processes such as soaking, washing, hulling, and milling. The flour has a dark yellow hue (characteristic of tartary buckwheat products), a fine texture, and can be mixed with wheat flour to make everyday foods like noodles, steamed buns, dumplings, and pastries.

Production Process: Raw tartary buckwheat selection → Cleaning → Drying → Hulling → Milling → Packaging (finished product).

Tartary Buckwheat Tea Production Process:

Tartary buckwheat tea is a healthy beverage made by roasting processed and hulled tartary buckwheat. The product has a crispy texture and a rich roasted grain aroma.

Production Process: Raw tartary buckwheat selection → Cleaning → Soaking → Steaming → Drying → Hulling → Roasting → Cooling → Packaging (finished product).

20 Corn and Grain Peeling Machines Equipped with Diesel Engines Shipped to Kenya

20 Corn and Grain Peeling Machines Equipped with Diesel Generators Successfully Loaded and Shipped to Kenya.

Vietnam 6Tons/Hour PeaS Cleaning and Peeling Line Successfully Shipped

On April 10, 2025, the 6-ton/hour peas cleaning and peeling production line ordered by a Vietnamese client was successfu

20T Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete sets